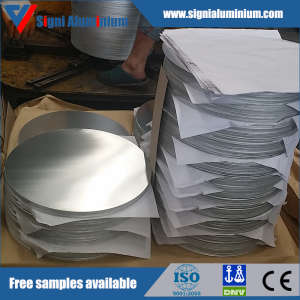

Round Aluminium Circles Plate for Frypan (1050, 1060, 1350, 3003)

The properties of aluminum circles (or shaped blanks) make them ideal for use in a number of markets including the cookware, automotive and lighting industries:

1. Low anisotropy, which facilitates deep drawing

2. Strong mechanical properties

3. High and homogeneous heat diffusion

4. Ability to be enameled, covered by PTFE (or others), anodized

5. Good reflectivity

6. High strength-to-weight ratio

7. Durability and resistance to corrosion

The properties of aluminum circles (or shaped blanks) make them ideal for use in a number of markets including the cookware, automotive and lighting industries:

1. Low anisotropy, which facilitates deep drawing

2. Strong mechanical properties

3. High and homogeneous heat diffusion

4. Ability to be enameled, covered by PTFE (or others), anodized

5. Good reflectivity

6. High strength-to-weight ratio

7. Durability and resistance to corrosion

| Aluminium circles |

| The properties of aluminum circles (or shaped blanks) make them ideal for use in a number of markets including the cookware, automotive and lighting industries: |

| Alloy | Temper | Thickness | Diameter |

| 1050, 1060, 1070, 1100, 3003 | O, H12, H14 | 0.36~10mm | 20~1200 |

| Remark: special specifications can be produced according to your requirement | |||

| Dimensions | ||

| Parameter | Range | Tolerance |

| Thickness for circles (mm) | 0.71 _ 6.35 | for 0.71 to 1.4 +/-0.08 |

| for 1.41 to 2.5 +0.1, -0.13 | ||

| for 2.51 to 4.0 +/-0.13 | ||

| for 4.01 to 5.00 +/-0.15 | ||

| for 5.01 to 6.35 +/-0.20 | ||

| Thickness for ovals (mm) | 1.75 _ 3.00 | for 1.75 to 2.5 +0.1, -0.13 |

| for 2.51 to 3.00 +/-0.13 | ||

| Diameter (mm) | 102 _ 1250 | (a) sheared circles +2, -0 |

| (b) punched circles +0.5, -0 | ||

| Earing | < 5% for ' O' temper < 9% for H12, H14, H16, H18 |

|

| Mechanical properties | |||||

| Alloy (AA) | Temper | %E (min) (at 50 mm gauge length) |

UTS (mpa) | Bend test: radius of bend (T=material thickness) |

|

| Min | Max | ||||

| 1050 | O | 29 | 55 | 95 | close |

| H14 | 6 | 95 | 125 | 1/2T | |

| H18 | 4 | 125 | - | 1T | |

| 1070 | O | 29 | 95 | - | close |

| H14 | 6 | 95 | 120 | 1/2T | |

| H18 | 4 | 120 | - | 1T | |

| 3003 | O | 25 | 90 | 130 | close |

| H14 | 5 | 130 | 180 | 1/2T | |

| H16 | 4 | 150 | 195 | 1T | |

| H18 | 3 | 170 | - | 3T | |

| Chemical composition | ||||

| Alloy (%) | AA 1050 | AA 1070 | AA 1100 | AA 3003 |

| Fe | 0.40 | 0.25 | 1.00 | 0.70 |

| Si | 0.25 | 0.20 | (Fr + Si) | 0.60 |

| Mg | 0.05 | 0.03 | - | - |

| Mn | 0.05 | 0.03 | 0.05 | 1.00 _ 1.50 |

| Cu | 0.05 | 0.04 | 0.05 | 0.05 _ 0.20 |

| Zn | 0.05 | 0.04 | 0.10 | 0.10 |

| Ti | 0.03 | 0.03 | 0.05 | 0.10 (Ti + Zr) |

| Cr | - | - | - | - |

| Each (others) | 0.03 | 0.03 | 0.05 | 0.05 |

| Total (Others) | - | - | 0.125 | 0.15 |

| Al | 99.50 | 99.70 | 99.00 | Remaining |

| Surface quality |

| Free from scratches, pit marks, rolling bands |

| Applicable standards |

| ASTM - B - 209M, Aluminium association _ aluminium standards and data, Hindalco manufacturing limits (as applicable). |

| Packing |

| The circles are packed in boxes or pallets with interleave paper, polythene, foam / thermocol. Pallets and boxes are strapped with hoop iron and clips. Silica gel packets are placed in the boxes for moisture protection. |